|

|

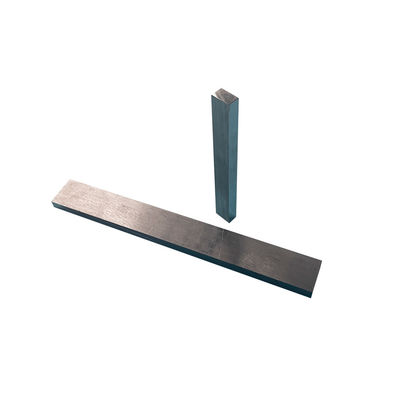

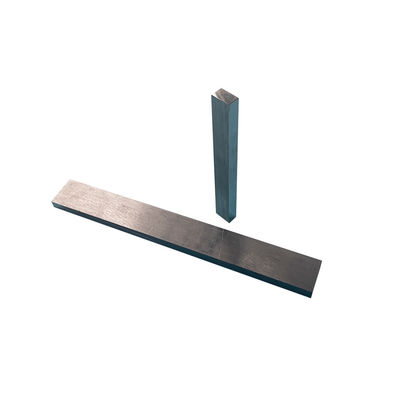

Płyta Invar 4J36 (UNS K93600) o bliskim zeru CTE, precyzyjna metrologia i zastosowania kriogeniczne

|

|

Szczegóły Produktu:

Zapłata:

|

| Material: | 4J36 | Supply Type: | Plate |

|---|---|---|---|

| Color: | Primary Color | Surface: | Bright and Smooth |

| Podkreślić: | Płyta Invar 4J36 do precyzyjnej metrologii,Płyta ze stopu o niskiej rozszerzalności cieplnej do zastosowań kriogenicznych,Płyta Invar UNS K93600 do metrologii |

||

Płyta Invar 4J36 o prawie zerowym CTE (UNS K93600)Precyzyjna metrologia i zastosowania kriogeniczne

OhmAlloy-4J36 (Invar), znany również generycznie jako FeNi36 (64FeNi w USA), to stop niklowo-żelazowy, charakteryzujący się wyjątkowo niskim współczynnikiem rozszerzalności cieplnej (CTE lub α).

Nazwa Invar pochodzi od słowa niezmienny, odnoszącego się do jego względnego braku rozszerzalności lub kurczenia się wraz ze zmianami temperatury.

Został wynaleziony w 1896 roku przez szwajcarskiego fizyka Charlesa Édouarda Guillaume. Otrzymał Nagrodę Nobla w dziedzinie fizyki w 1920 roku za to odkrycie, które umożliwiło ulepszenia w instrumentach naukowych.

OhmAlloy-4J36 (Invar) jest stosowany tam, gdzie wymagana jest wysoka stabilność wymiarowa, np. w precyzyjnych instrumentach, zegarach, sejsmicznych miernikach pełzania, ramach masek cieniowych telewizorów, zaworach w silnikach i zegarkach antymagnetycznych. W geodezji, gdy ma być wykonywane niwelowanie precyzyjne (wysokiej precyzji), używana jest łata niwelacyjna (tyczka niwelacyjna) wykonana z Invaru, zamiast drewna, włókna szklanego lub innych metali. W niektórych tłokach stosowano rozpórki Invar, aby ograniczyć ich rozszerzalność cieplną wewnątrz cylindrów.

Normalny skład %

| Ni | 35~37.0 | Fe | Bal. | Co | - | Si | ≤0.3 |

| Mo | - | Cu | - | Cr | - | Mn | 0.2~0.6 |

| C | ≤0.05 | P | ≤0.02 | S | ≤0.02 |

Typowe właściwości fizyczne

| Gęstość (g/cm3) | 8.1 |

| Rezystywność elektryczna w 20℃(Ωmm2/m) | 0.78 |

| Współczynnik temperaturowy rezystywności(20℃~200℃)X10-6/℃ | 3.7~3.9 |

| Przewodność cieplna, λ/ W/(m*℃) | 11 |

| Punkt Curie Tc/ ℃ | 230 |

| Moduł sprężystości, E/ Gpa | 144 |

Współczynnik rozszerzalności

| θ/℃ | α1/10-6℃-1 | θ/℃ | α1/10-6℃-1 |

| 20~-60 | 1.8 | 20~250 | 3.6 |

| 20~-40 | 1.8 | 20~300 | 5.2 |

| 20~-20 | 1.6 | 20~350 | 6.5 |

| 20~-0 | 1.6 | 20~400 | 7.8 |

| 20~50 | 1.1 | 20~450 | 8.9 |

| 20~100 | 1.4 | 20~500 | 9.7 |

| 20~150 | 1.9 | 20~550 | 10.4 |

| 20~200 | 2.5 | 20~600 | 11.0 |

Typowe właściwości mechaniczne

| Wytrzymałość na rozciąganie | Wydłużenie |

| Mpa | % |

| 641 | 14 |

| 689 | 9 |

| 731 | 8 |

Współczynnik temperaturowy rezystywności

| Zakres temperatur, ℃ | 20~50 | 20~100 | 20~200 | 20~300 | 20~400 |

| aR/ 103 *℃ | 1.8 | 1.7 | 1.4 | 1.2 | 1.0 |

Proces obróbki cieplnej

| Proces obróbki cieplnej | |

| Wyżarzanie w celu odprężenia | Ogrzewać do 530~550℃ i trzymać 1~2 h. Schłodzić |

| wyżarzanie | Aby wyeliminować utwardzanie, które może wystąpić w procesie walcowania na zimno, ciągnienia na zimno. Wyżarzanie wymaga ogrzania do 830~880℃ w próżni, trzymać 30 min. |

| Proces stabilizacji |

1) W ośrodku ochronnym i ogrzać do 830 ℃, trzymać 20min. ~ 1h, hartować 2) Ze względu na naprężenia powstałe podczas hartowania, ogrzać do 315℃,trzymać 1~4h. |

| Środki ostrożności |

1) Nie można utwardzać przez obróbkę cieplną 2) Obróbka powierzchni może obejmować piaskowanie, polerowanie lub trawienie. 3) Stop można wytrawiać 25% roztworem kwasu solnego w temperaturze 70 ℃ w celu oczyszczenia utlenionej powierzchni |

Jaka jest różnica między Inconelem a Invarem 36?

Wybór między tymi dwoma powinien być oparty na specyficznych wymaganiach danego zastosowania. Invar nadaje się do zastosowań, które wymagają niskiego współczynnika rozszerzalności cieplnej. Z drugiej strony, Conel jest idealnym rozwiązaniem, które wymaga wysokiej wytrzymałości i odporności na ciepło.

![]()

Opakowanie

![]()

![]()

Osoba kontaktowa: Mr. Qiu

Tel: +8613795230939

-

Invar Fe-Ni36 4J36 Stop niklu o niskiej rozszerzalności Żelazo 1,2 ppm ° C Antykorozyjny

-

4J29 Kovar FeNi29Co17 Uszczelniające szkło stopy o niskiej rozszerzalności

-

Kovar Low Alloy 4J29 Strip Strip - Metalowa uszczelka do żarówek

-

Zestaw 42 FeNi42 Pasek uszczelniający do uszczelniania szkła z ceramiki do metalu

-

Kovar 4J29 Precyzja pręta uszczelniającego wypolerowana do hermetycznych przechodów

-

Precyzyjne stop 42 FeNi42 Pasek uszczelniający niska ekspansja